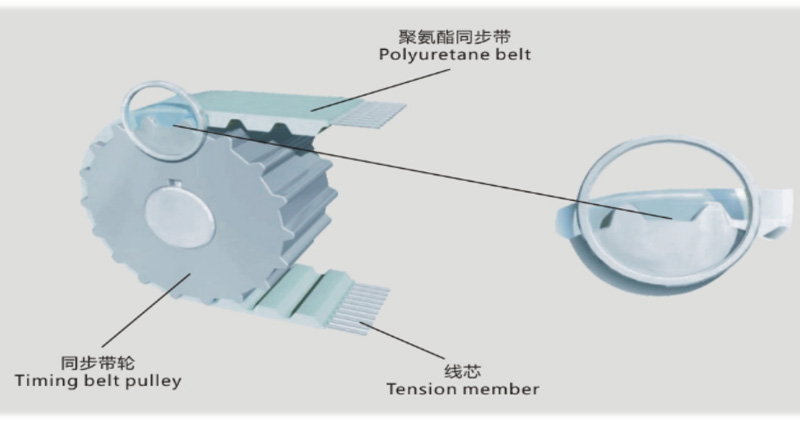

Polyurethane timing belt structure:

1.PU belt body

2. Core: steel wire, stainless steel, Kevlar wire

3. Tooth surface (tooth back) plus cloth

4. Backing: PVC, PU, APL, sponge, rubber, etc.

The advantages of polyurethane timing belt:

Use steel wire rope (Kevlar, nylon, polyester core) or glass fiber as the strength layer, and outer ring with polyurethane or neoprene Pulley meshing. Moreover, the product does not need lubrication, no slip, no pollution, and less noise; the transmission efficiency is over 98%, the speed ratio range can reach 1:10, the allowable linear speed can reach 50m/s, and the transmission rate can range from several hundred watts to several watts. 100 kilowatts, also suitable for multi-shaft transmission.

The product has good dynamic bending performance and anti-cracking performance, excellent ozone performance, and also has the characteristics of aging resistance, heat resistance and wear resistance.

Timing belt operation mode:

The synchronous belt drive is composed of an endless belt with equidistant teeth on the inner peripheral surface and a pulley with corresponding teeth. During operation, the belt teeth mesh with the tooth grooves of the pulley to transmit motion and power. A new type of belt drive that combines the advantages of belt drive and chain drive gear drive.

Synchronous belt and pulley structure display (synchronized transmission = synchronous belt + synchronous pulley). First, ensure that the belt and pulley Is it a correct match.

Introduction of polyurethane raw materials

Polyurethane: The English name is Polyurethane (PU for short), which is produced by the reaction of polyisocyanate and polyol polymer. It can be made into foam plastic, rubber, paint, adhesive, fiber, synthetic leather waterproof material and other products. Polyurethane raw materials mainly include: isocyanates, polyester polyols (generated by the reaction of polyols and polyacids, commonly used polyacids are adipic acid, commonly used polyols are 1,2 butanediol, ethylene glycol, etc.), polyether polyols ( Commonly used are PPG, POP, PTMEG, etc.), solvents, chain extenders, and various additives. Polyurethane is divided into thermoplastic polyurethane (referred to as TPU), cast polyurethane (referred to as CPU) and mixing polyurethane (referred to as MPU) according to the processing method.

Advantages of polyurethane materials:

1. High wear resistance (see the attached table for comparison of wear resistance of various polymers)

2. No debris will be produced during the wear process to contaminate other mechanical parts

3. Good toughness without adding plasticizer

4. Will not reach the level of hardening and aging like rubber over time

5. Good tolerance, oil, grease, water, etc.